SRS Sludge Removal Systems Trailer

This self-contained trailer was designed to support the equipment your team will need to remove heavy sludge from the tank. The trailer features a control station, hydraulic power unit, hose reel assembly, diesel fuel tank, generator, side door, and pulldown rear door ramp.

The control station’s ergonomic design, with a flat-screen monitor, with two joysticks that correspond to the cannon you are using (roof or side cannon) or a combination of an RMC and 360 MIN.

Trailer Specifications

Features of the SRS 24' Trailer

Custom built trailer for SRS with a side door to the control room, rear hydraulic hose doors to power 360 MIN and RMC units, and rear folding door for the easy roll-out of equipment.

SRS Sludge Removal Systems Remote Manway Cannons Side and Roof

360min Manway Injection Nozzle Patent Pending

This equipment is used to lower the sludge level in the tank so the roof RMC can be installed later into this tank’s manway. Confined space permits and a rescue team are required for the installation of each 360MIN and RMC units with crane support for this lift unto the floating roof.

The plan is to safely open the manway to insert the MIN 360 on the roof manways, secured with C-clamps and ground for inspection. The hydraulic hoses will be connected to the 360-degree direction controlled in the trailer. The 360 MIN has both outside and inside pointer to view either on the roof or inside the tank once the RMC camera and light are working at another manway.

Once the unit is bolted together, it will be 6 feet long, just inches off the bottom of the tank if on maintenance legs. This unit will inject water, diesel, or LCO at 225 GPM at 100 PSI.

We can offer different length extensions per your needs.

Once you have the sludge level down to the floor or enough for the roof cannon to be installed without getting the camera and light in the sludge, remove the 360 MIN and install the cannon.

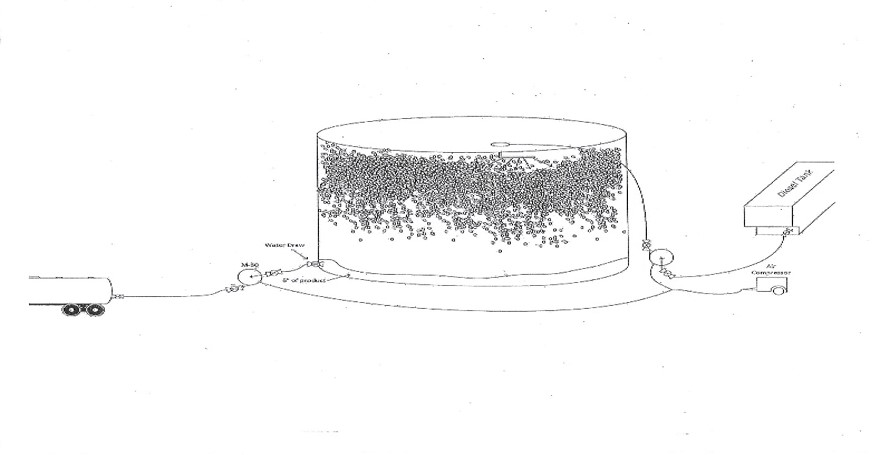

Tank Atomizer Degasser (TAD) Patent Pending the Solution for Degassing Tanks

WESTATES TAD system was designed to lower the PPM levels of the vapor space of floating and fixed roof tanks. This degassing process is an internal manway atomizer that will replace the roof manway for the degassing of high LEL vapor space. The TAD will bolt to an appropriate aluminum adaptor plate to adjust for a tank standard manway.

The TAD unit will extend through the roof of the tank manway 36 inches or longer for the atomizer to spray a pattern horizontally at 10 GPM or 28.5 barrels per hour. Just C-clamp the TAD mounting plate onto the manway (assure grounding) and connect the supply hose to the feed pipe inlet, turn on the feed pump.

The TAD has multiple special designed atomizers to create a fine mist of diesel or WESTATES Pure Oil Chemistries to spray out in a 360-degree pattern. This action will atomize the internal vapor space and reduce vapor in air concentrated fog, which will absorb the gas vapors reducing the PPM levels to meet SCAQMD requirements.

This procedure will eliminate the need to conduct typical exterior degassing operations by atomizing the liquid and adsorption of the tank’s vapor. The TAD unit is built from stainless steel with many options, even a storage rack to keep safe when transported.

Tank Atomizer Degasser (TAD) Patent Pending the Solution for Degassing Tanks

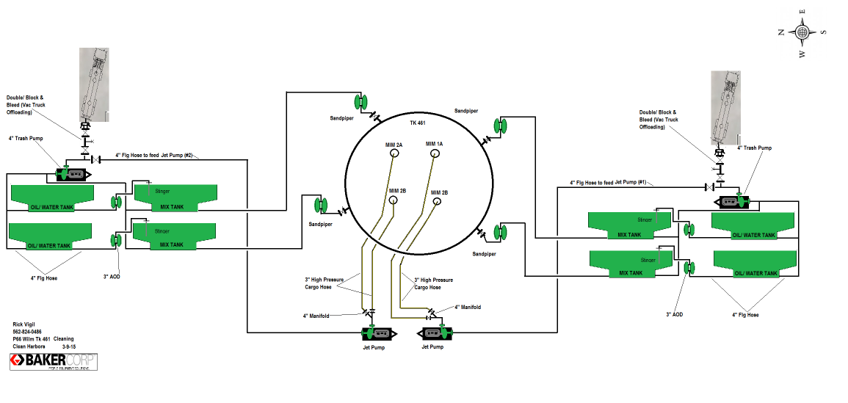

SRS WESTATES equipment was used to remove 13 feet of solids see the Baker’s plot plan given to the refinery and contractors 4-MIN (Manway Injection Nozzle), and RMC (Remote Manway Cannon) Baker supplied everything else